Driving Business Excellence with CNC Lathe Parts Factories: The Future of Metal Fabrication

In the rapidly evolving landscape of modern manufacturing, the role of cnc lathe parts factories has become increasingly pivotal. These specialized metal fabricators not only supply high-precision components but also revolutionize how industries approach production, quality, and efficiency. Whether it’s automotive, aerospace, machinery, or consumer electronics, the backbone of success often lies in the mastery of CNC lathe machining facilities. This comprehensive guide delves into the imperative role of cnc lathe parts factories, illustrating how they shape a competitive and innovative business environment.

Understanding the Significance of CNC Lathe Parts Factories in Modern Industry

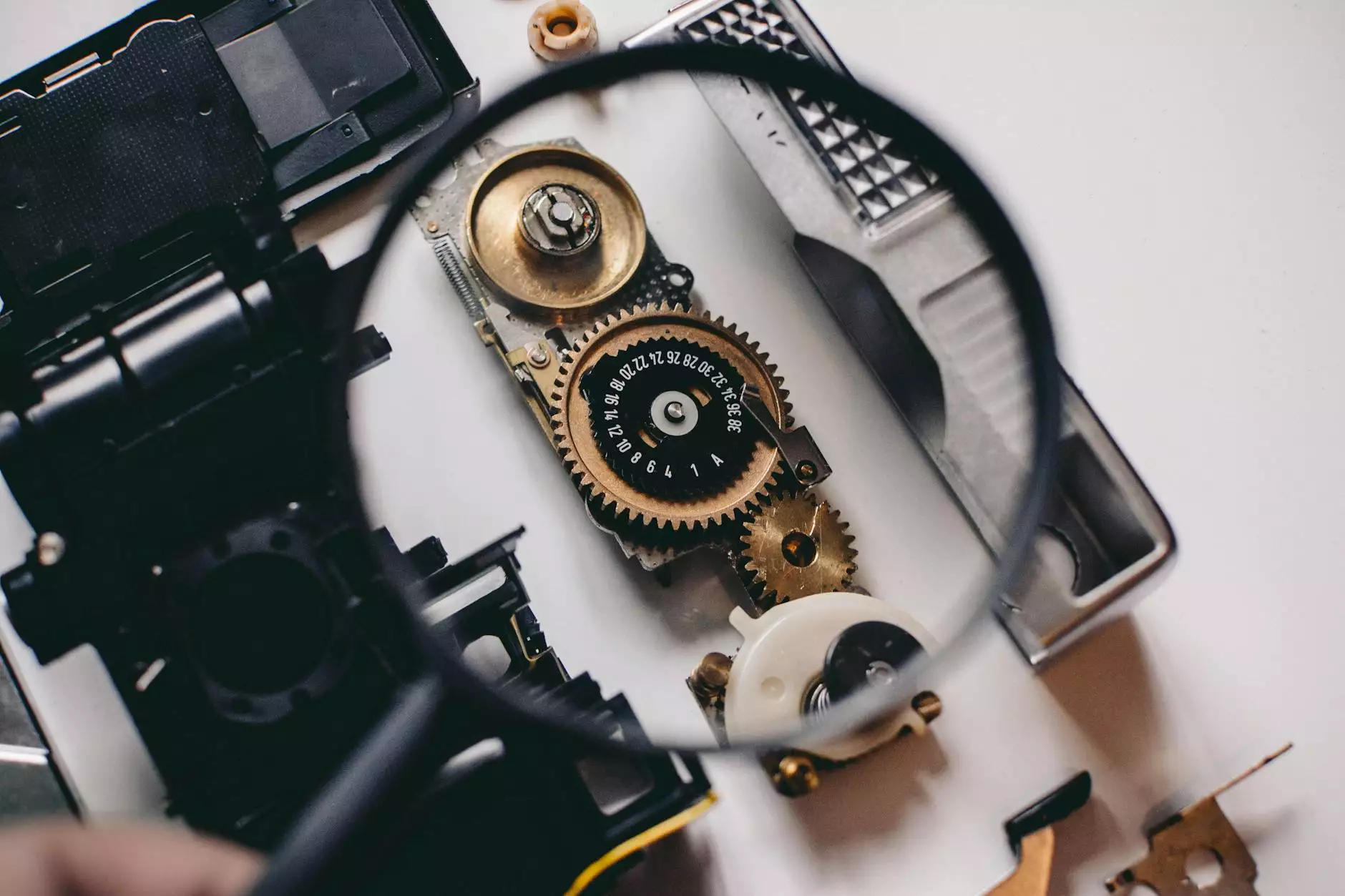

CNC (Computer Numerical Control) lathe machines are the cornerstone of precision manufacturing. They enable the production of complex, high-tolerance parts with unparalleled consistency and efficiency. Factories specializing in CNC lathe parts serve as the primary hubs where raw materials are transformed into critical components for various industries.

What Are CNC Lathe Parts Factories?

These factories are facilities equipped with state-of-the-art CNC lathe machines that automate the turning, cutting, and shaping of metal and other materials. They feature an integrated workflow of design, programming, machining, and finishing — delivering precision parts in large quantities, often with tight tolerances and complex geometries.

The Evolution of Metal Fabricators with CNC Technology

Transitioning from traditional manual machining to CNC technology has marked a significant milestone in manufacturing. Advanced CNC lathe parts factories harness the power of automation, robotics, and real-time quality control to produce parts that set industry standards.

Core Advantages of Partnering with CNC Lathe Parts Factories

Engaging with skilled cnc lathe parts factories offers numerous strategic benefits that can elevate your business to new heights:

- Unmatched Precision and Consistency: CNC machinery ensures every part meets exact specifications, reducing errors and waste.

- High Efficiency and Productivity: Automated processes accelerate production timelines, enabling faster delivery to market.

- Cost Optimization: Mass production with minimal material waste lowers overall manufacturing costs.

- Customization Flexibility: CNC technology allows rapid adaptation to design changes and bespoke requirements.

- Enhanced Quality Control: Real-time monitoring and testing ensure quality standards are consistently met.

- Reduced Labor Dependency: Automation minimizes manual intervention, reducing labor costs and human error.

How CNC Lathe Parts Factories Are Revolutionizing Industries

The impact of cnc lathe parts factories extends across multiple sectors, transforming manufacturing paradigms through innovation and capability expansion.

Automotive Industry

Precision engine components, transmission parts, and critical fittings are produced with remarkable accuracy, ensuring the safety and performance of vehicles. CNC lathe factories enable automotive manufacturers to meet tight tolerances required for high-performance vehicles.

Aerospace Sector

In aerospace, where safety and reliability are paramount, metal fabricators specializing in CNC lathe parts deliver components that withstand extreme conditions and stringent certifications. From turbine blades to structural fittings, the quality precision is indispensable.

Electronics and Consumer Goods

Miniaturization trends demand intricate metal parts and housings. CNC lathe factories facilitate the production of tiny yet complex components, supporting innovation in consumer electronics and smart devices.

Industrial Equipment and Machinery

Heavy machinery parts requiring durability and detailed machining are efficiently produced at CNC lathe facilities, ensuring longer service life and operational reliability.

The Key Factors to Consider When Choosing a CNC Lathe Parts Factory

Constructing a successful partnership with a cnc lathe parts factory requires careful evaluation of several core factors:

- Technical Capabilities: Does the factory possess advanced CNC equipment capable of handling your project’s complexity?

- Material Expertise: Can they work with diverse materials like stainless steel, aluminum, titanium, or special alloys?

- Quality Assurance Protocols: Do they follow rigorous standards such as ISO 9001, TS16949, or industry-specific certifications?

- Production Capacity and Scalability: Can they meet your volume requirements now and accommodate future growth?

- Lead Time and Flexibility: What is their typical turnaround time? Are they adaptable to urgent or changing demands?

- Cost-Effectiveness: How competitive are their pricing models without compromising quality?

- Technical Support and Communication: Do they offer detailed technical assistance and seamless communication throughout the project?

Enhancing Your Business with a Trusted cnc lathe parts factory Partner

Collaborating with a reputable metal fabricator like DeepMould.net can create a significant competitive advantage. Their expertise in cnc lathe parts manufacturing ensures that your products are optimized for performance, durability, and cost-efficiency.

Integrated Manufacturing Solutions

DeepMould.net offers comprehensive solutions that encompass design optimization, rapid prototyping, and mass production, streamlining your entire supply chain and reducing reliance on multiple vendors.

Customization and Innovation

With advanced CNC lathe technology and skilled engineers, they support complex geometries, tight tolerances, and innovative materials, pushing the boundaries of what your products can achieve.

Quality Management and Certification

Enforcing strict quality control measures, DeepMould.net routinely complies with international standards, providing transparency and assurance for high-stakes applications.

Future Trends in CNC Lathe Parts Manufacturing

Keeping pace with technological advancements is crucial for staying competitive. Upcoming trends include:

- Automation and Artificial Intelligence: Enhanced machine learning algorithms for predictive maintenance and process optimization.

- Additive Manufacturing Integration: Hybrid processes combining CNC machining with 3D printing for complex, lightweight components.

- Smart Factories and Industry 4.0: Incorporating IoT-enabled machinery for real-time monitoring, data collection, and workflow automation.

- Sustainable Manufacturing: Adoption of eco-friendly materials and energy-efficient processes to meet environmental standards.

Conclusion: Why Your Business Needs a Reliable cnc lathe parts factory

Ultimately, the success of any manufacturing enterprise hinges on the quality of its components and the efficiency of its supply chain. Partnering with a professional, experiencedcnc lathe parts factory like DeepMould.net transforms your production capabilities, enabling you to attain superior product quality, faster time-to-market, and competitive pricing.

Investing in top-tier metal fabricators that specialize in CNC lathe parts is not just a procurement decision; it is a strategic move toward sustainable growth, innovation, and industry leadership.

Embrace the future of manufacturing by leveraging advanced CNC lathe technology and expert craftsmanship—drive your business forward today.