Unlocking the Future of Manufacturing: Rapid Prototyping Services Suppliers

In today’s fast-paced manufacturing landscape, the demand for rapid prototyping services suppliers has surged dramatically. These suppliers are essential in bridging the gap between concept and reality, providing businesses with the tools necessary to innovate rapidly and efficiently. Whether you're a start-up looking to develop a new product or an established company seeking to improve your manufacturing processes, understanding the role and advantages of rapid prototyping is crucial.

What is Rapid Prototyping?

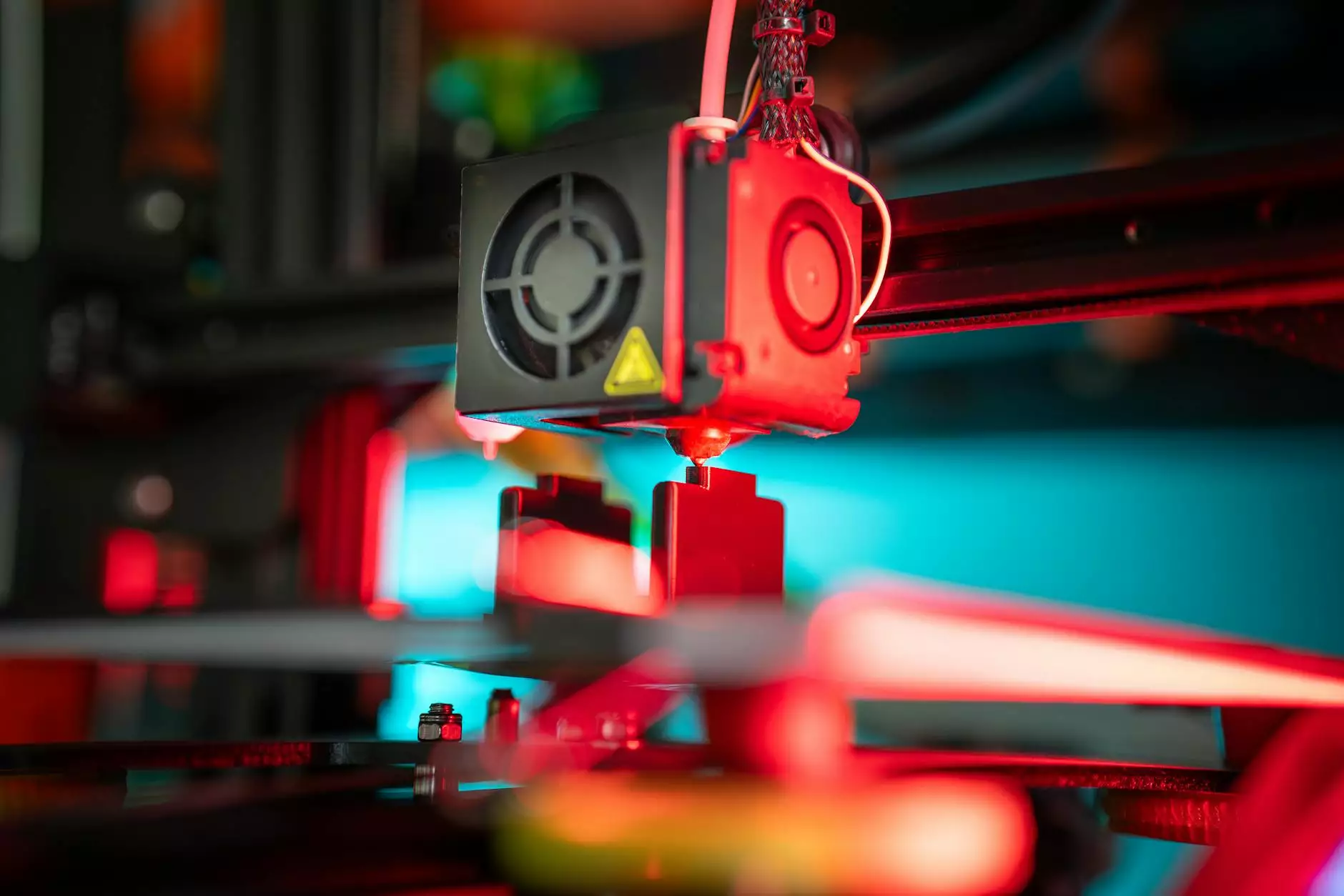

Rapid prototyping is a group of techniques used to quickly fabricate a scale model of a physical part or assembly using three-dimensional computer-aided design (CAD) data. The primary objective of rapid prototyping is to speed up the product development process by facilitating early testing and feedback. This approach not only reduces the time involved in product development but also helps in identifying design flaws and potential issues before full-scale manufacturing.

The Evolution of Manufacturing: The Role of Rapid Prototyping Services Suppliers

Over the years, the manufacturing industry has undergone significant changes driven by technological advancements. Rapid prototyping services suppliers have played a critical role in this evolution, enabling manufacturers to adopt more agile and flexible production approaches. These services provide a plethora of benefits:

- Accelerated Product Development: Rapid prototyping significantly reduces the time from design to market.

- Cost Efficiency: It minimizes the costs associated with traditional manufacturing methods by allowing changes without significant financial implications.

- Enhanced Collaboration: Prototypes can be shared among teams for collaborative feedback, fostering innovation and creativity.

- Reduced Risk: Early detection of design flaws leads to less risk of costly mistakes during mass production.

- Customization: Suppliers can create tailored prototypes to meet specific project needs.

Why Partner with Leading Rapid Prototyping Services Suppliers?

Choosing the right rapid prototyping services supplier can make all the difference in the success of your project. Here’s why partnering with top-tier suppliers like Deep Mould is essential:

1. Advanced Technology and Expertise

Leading suppliers invest in state-of-the-art technology, including 3D printing, CNC machining, and laser cutting. This investment ensures that clients receive the highest quality prototypes that accurately reflect the final product. Moreover, these suppliers employ skilled engineers and designers who bring deep knowledge and experience to the table, enhancing the overall quality of the prototypes created.

2. A Comprehensive Range of Materials

One of the biggest advantages of working with established rapid prototyping services suppliers is the availability of a wide range of materials. Suppliers can work with various substances, including plastics, metals, and composites, enabling the creation of prototypes that closely mimic the intended final products. For example, metal fabricators can produce prototypes using aluminum and stainless steel, ensuring prototypes are durable and functional.

3. Scalability and Flexibility

Rapid prototyping offers businesses unmatched flexibility. As projects evolve, suppliers can quickly adapt to changes in design and production requirements. This adaptability is crucial in today’s market, where consumer preferences shift rapidly and innovation is key to staying competitive.

Applications of Rapid Prototyping in Metal Fabrication

The metal fabrication industry has significantly benefited from rapid prototyping services. Here are some of the most common applications:

1. Custom Tooling

Prototyping is instrumental in creating custom tools and fixtures. By developing prototypes of tooling designs, metal fabricators can evaluate functionality, ergonomics, and efficiency before investing in full-scale production.

2. Product Testing

Different industries require rigorous testing of components and assemblies. Rapid prototyping allows for early testing to ensure products meet industry specifications and safety standards, thus avoiding costly recalls or redesigns later.

3. Small Batch Production

For special projects, rapid prototyping allows for small production runs without the need for significant investment in large-scale manufacturing equipment. This approach is especially beneficial for niche markets where demand is irregular.

Key Considerations When Selecting Rapid Prototyping Services Suppliers

When searching for the right rapid prototyping services suppliers, it’s important to consider various factors to ensure you make the best choice for your business:

1. Industry Experience

Choose suppliers with proven experience in your specific industry, as they will understand your unique challenges and requirements.

2. Reviews and Testimonials

Research client feedback and case studies to gauge the quality and reliability of the supplier’s services. Positive testimonials can provide added assurance of their capability.

3. Customer Support

Effective communication and support are essential throughout the prototyping process. Select suppliers that offer responsive customer service to address your questions promptly.

4. Post-Production Services

Look for suppliers that offer post-production services, such as finishing, assembly, and quality control, to streamline the production process.

Future Trends in Rapid Prototyping

The future of rapid prototyping is promising, with several key trends expected to shape its development:

1. Integration of AI and Machine Learning

The incorporation of AI and machine learning will enhance design optimization and improve production efficiency, enabling quicker iterations of prototypes.

2. Sustainable Manufacturing Practices

As industries focus on sustainability, rapid prototyping will increasingly incorporate eco-friendly materials and practices to reduce waste and environmental impact.

3. Enhanced Collaboration Tools

The adoption of advanced collaboration tools will facilitate real-time feedback from multiple stakeholders, further accelerating the prototyping process.

Conclusion: Embrace the Future with Rapid Prototyping Services Suppliers

The rapid evolution of technology has paved the way for rapid prototyping services suppliers to become invaluable partners in the manufacturing process. By embracing these innovative solutions, companies can enhance their product development capabilities, reduce costs, minimize risks, and bring their designs to market faster than ever before. Whether you’re a metal fabricator or any other industry, incorporating rapid prototyping into your workflow is not just an advantage; it’s becoming a necessity for success.

To explore more about how rapid prototyping services can transform your manufacturing process, visit Deep Mould today! Discover a range of solutions that can elevate your business to new heights.

© 2023 Deep Mould. All rights reserved.