Mariano Welding: Crafting Perfection in Metal Fabrication

In the world of metal fabrication, few names stand out as prominently as Mariano Welding. Serving various industries with high-quality metalworking solutions, Mariano Welding has established itself as a trusted leader among metal fabricators.

Why Choose Mariano Welding?

As businesses look for reliable partners in metal fabrication, the selection often boils down to quality, expertise, and performance. Here are some compelling reasons why Mariano Welding should be your preferred choice:

- Expert Craftsmanship: Our team of skilled welders and fabricators brings years of experience, ensuring that every project is handled with the utmost care and precision.

- State-of-the-Art Equipment: We utilize the latest technology in welding and metal fabrication, allowing for improved accuracy and efficiency.

- Custom Solutions: We understand that every project is unique. Our ability to offer tailored solutions meets the specific needs of our clients.

- Commitment to Sustainability: Mariano Welding actively seeks sustainable practices, including recycling scrap metal and employing eco-friendly techniques.

Our Services: Comprehensive Metal Fabrication Solutions

At Mariano Welding, our range of services is designed to encompass all facets of metal fabrication. Here’s a detailed look at what we offer:

1. Custom Metal Fabrication

Whether you need a one-off piece or mass production, our expert team is adept at creating custom solutions. With Mariano Welding, you gain access to:

- Design and Prototyping: Collaborate with our designers to create prototypes to your specifications.

- Full Production Runs: We can efficiently scale from prototype to full production.

- Diverse Material Options: We work with a variety of metals including stainless steel, aluminum, and carbon steel.

2. Welding Services

Our skilled welders excel in various welding techniques, such as:

- MIG Welding: Ideal for projects requiring high-speed and versatility.

- TIG Welding: Best for thin materials, providing exceptional control and finishing quality.

- Stick Welding: Robust and reliable, perfect for outdoor work and heavy-duty fabrication.

3. Metal Repairs and Maintenance

Preventive maintenance and timely repairs can extend the life of your metal products. Our services include:

- Inspection and Assessment: Thorough evaluations to determine the state of your metals.

- Restoration Services: Repairing and restoring parts to maintain functionality.

- Regular Maintenance Contracts: Keeping your equipment in top form with scheduled services.

Industries We Serve

Our versatility allows us to serve a variety of industries effectively. Some of the key sectors benefiting from Mariano Welding's expertise include:

- Construction: Providing durable metal structures and supports for buildings.

- Aerospace: Delivering lightweight and strong components for aircraft manufacturing.

- Automotive: Custom fabrication for parts and prototypes.

- Energy: Engaging in projects related to renewable energy sectors.

Quality Assurance: Our Meeting Standards

Quality is the cornerstone of Mariano Welding. We adhere to stringent quality control processes that ensure every project meets international standards.

ISO Certifications

Our dedication is reflected in our ISO certifications, ensuring all our processes meet rigorous criteria in quality and safety.

Customer Satisfaction

We believe in building long-term relationships with our clients. Feedback is actively encouraged to improve our services continually.

Innovation at Mariano Welding

Innovation is at the heart of Mariano Welding. We invest in the latest technologies to stay ahead of industry trends. Our commitment to research and development has enabled us to introduce:

- Advanced Automation: Utilizing robotics to streamline production processes and enhance precision.

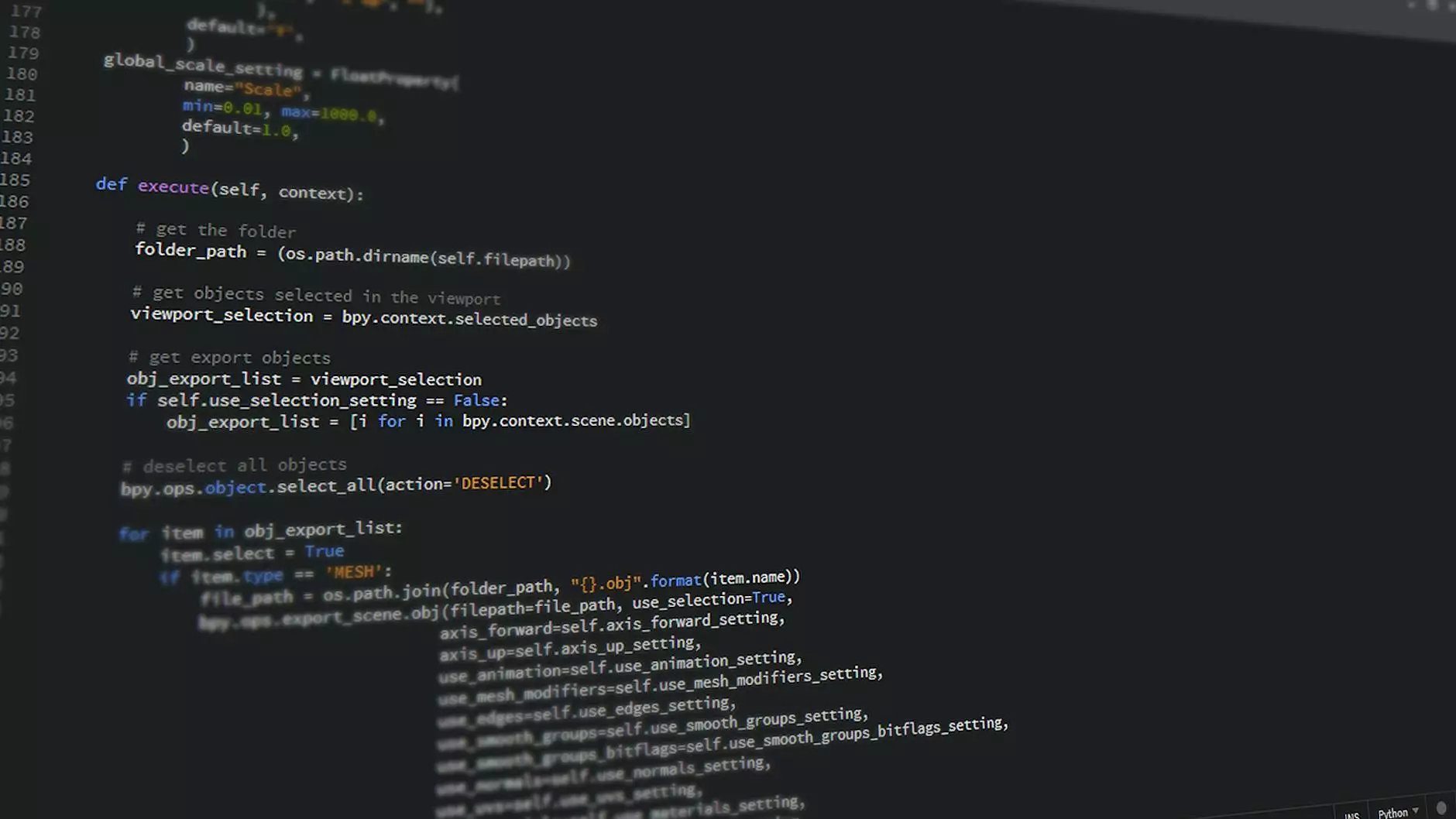

- CAD/CAM Software: Embracing digital fabrication techniques allows for enhanced design flexibility.

Case Studies: Success Stories from Mariano Welding

We take pride in our past projects that showcase our capability and commitment. Here are a couple of case studies:

Case Study 1: Custom Steel Framework for a High-Rise Building

A leading construction firm approached us for a custom framework for a skyscraper. With a tight deadline and specific requirements, Mariano Welding delivered within the timeframe and exceeded quality expectations. Our design improved the overall stability of the structure, earning accolades from engineers and architects alike.

Case Study 2: Manufacturing Components for Electric Vehicles

With the rise of electric vehicle production, an automotive company sought our expertise for lightweight component fabrication. We employed specialized techniques to ensure optimal performance while reducing overall weight. The project not only improved the vehicle's efficacy but also enhanced our client’s market positioning in the burgeoning EV sector.

Getting Started with Mariano Welding

Ready to elevate your project with top-tier metal fabrication? Here’s how you can commence your journey with Mariano Welding:

1. Consultation

Contact us for a detailed consultation. Our experts will work with you to understand your needs and propose the most effective solutions.

2. Project Proposal

We will provide a comprehensive proposal outlining the project scope, timelines, and estimated costs.

3. Execution

Once approved, our team will initiate the project, keeping you updated throughout the process.

Conclusion: The Future of Metal Fabrication is Here

Mariano Welding is not just a service provider; we are your partners in success. Our commitment to quality, innovation, and customer satisfaction sets us apart in the competitive landscape of metal fabrication. Join us in crafting the future!

Contact Us Today!

If you have questions or wish to start a project, visit our website at brothersmariano.com or call us directly. Let’s bring your visions to life through exceptional welding and metal fabrication.